Are Hygienic Storage Tanks Hard To Maintain

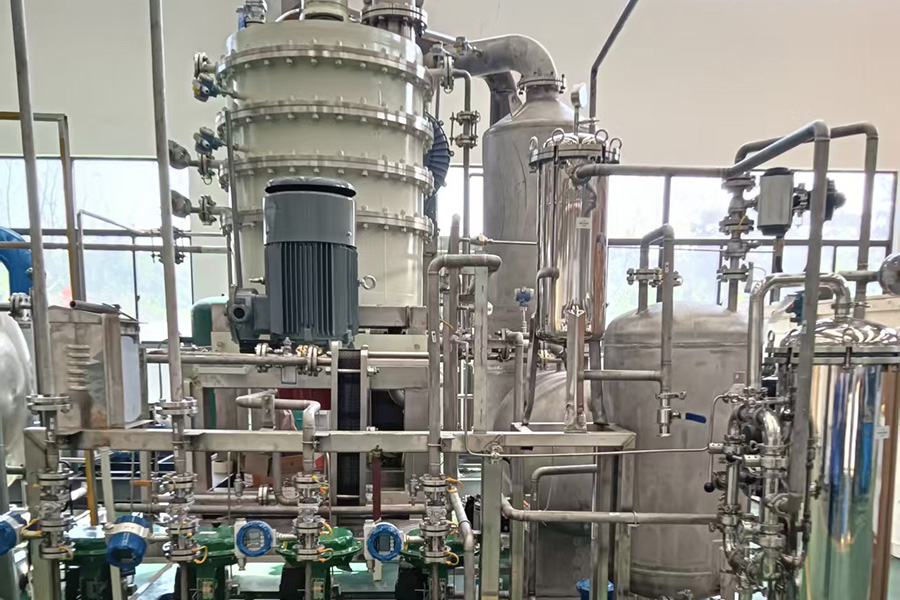

The stainless steel storage tank system is a foundational component for modern manufacturing in industries where cleanliness and material purity are essential. From food and beverage processing to pharmaceutical production, proper tank maintenance ensures product integrity and operational efficiency. Many users have raised questions about how difficult these tanks are to clean and maintain, and this article explores the real challenges and practical solutions for long-term upkeep.

A Hygienic Storage Tank is designed with smooth, non-porous interior surfaces that facilitate cleaning and prevent microbial harborage. This is achieved by polishing with specialized finishing techniques, often targeting very low surface roughness values (Ra values) to minimize crevices where bacteria and residue could accumulate. However, while the design supports cleanliness, maintaining that state requires deliberate procedures.

Common Maintenance Challenges

Many users’ concerns center on residue buildup and sanitation effectiveness. In routine operations, especially in food or pharmaceutical facilities, organic residues and mineral deposits can accumulate on internal surfaces if cleaning is inconsistent. Even though Stainless Steel Storage Tanks are inherently corrosion-resistant and non-reactive, buildup over time can create hotspots for bacteria if not properly addressed.

Another common issue is seal and gasket wear. These components are essential for preventing leaks and maintaining tank integrity. Over time, seals can degrade due to temperature fluctuations or exposure to cleaning chemicals, causing to leakage or contamination risk. Periodic inspection and replacement help mitigate this.

Practical Maintenance Strategies

To manage maintenance more effectively, many facilities implement a Clean-in-Place (CIP) system. CIP allows sanitization without disassembling the tank, reducing downtime and manual labor. It uses recirculated cleaning solutions at controlled temperatures to remove residues and maintain internal hygiene levels.

In addition to CIP:

Scheduled cleaning cycles ensure that tanks are cleaned after each production batch, especially crucial in food and beverage operations.

Routine visual inspections help detect early signs of contamination or surface irregularities that could compromise hygiene.

Proper drain design and sloped bottom surfaces encourage complete drainage, eliminating stagnant liquid that could foster microbial growth.

Material Selection Matters

The grade of stainless steel used in storage tanks directly influences maintenance. Common options include 304 and 316L stainless steel, with 316L typically offering nice resistance to chloride corrosion and is often selected for higher-risk environments.

Material choice affects not only corrosion resistance but also ease of cleaning. Smoother interior finishes, whether achieved through mechanical polishing or electropolishing, reduce the required cleaning effort and help sustain long-term hygienic performance.

Role of Design and Installation

Good design starts with a focus on hygienic principles: impervious surfaces, absence of sharp corners, and welds that are flush and polished. Such engineering decisions reduce the potential for residue retention.

Moreover, thoughtful piping and valve placement can reduce dead legs—areas where stagnant material can remain—making cleaning more thorough and efficient.

Why Zhejiang Xinchuangxing Technology Co., Ltd. Focuses on Maintainability

At Zhejiang Xinchuangxing Technology Co., Ltd., we consider maintenance needs early in tank design. By integrating CIP-ready features, optimized drain geometry, and polished interior surfaces, our tanks help reduce manual cleaning time and support easier maintenance workflows across industries. These design priorities reflect the practical concerns voiced by plant operators and production engineers.

En

En

русский

русский Español

Español عربى

عربى