Interception-Type Wet Desulfurization Equipment

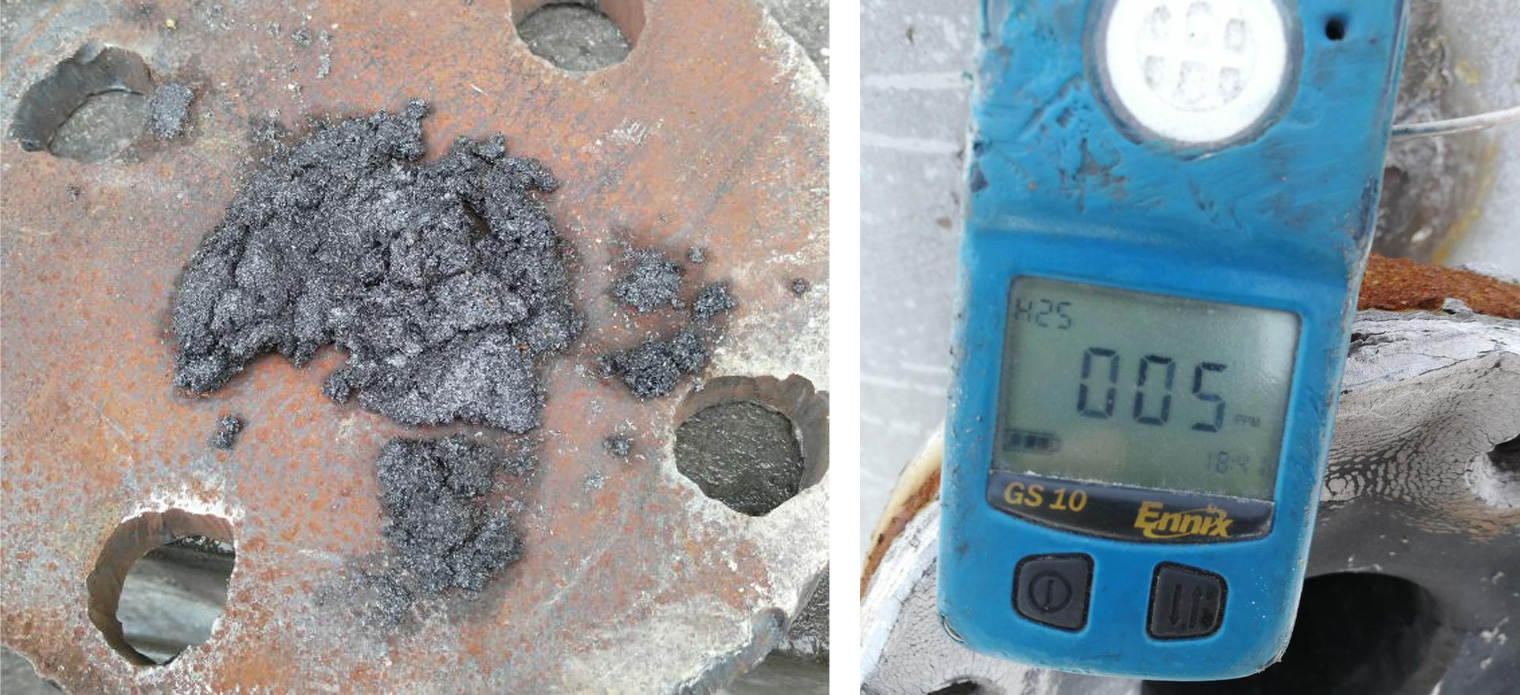

Our desulfurization technology utilizes a high-gravity field to achieve excellent purification results. This field generates strong mass and heat transfer capabilities. Through high-speed rotation, the desulfurizer liquid is dispersed into minuscule films, filaments, and droplets as it passes through the interception layer of the wet desulfurization equipment.

This process, facilitated by the high-gravity field, creates a large specific surface area and a rapidly updated phase interface, ensuring full gas-liquid contact. The capture of sulfur-containing gases like H2S and SO2 is highly selective. This selectivity is due to the collision effect from mechanical rotation, the liquid film's capture effect, and the filtering action of the droplets themselves on low-solubility gases.

Simultaneously, the rotating cut-off ring applies a high shear stress to the liquid, splitting it into incredibly tiny droplets and thin films. The continuous change in direction of the gas and liquid channels significantly extends contact time, providing a superior surface for the absorption of easily dissolved gases.

In the event that impurity gases like H2S and SO2 pass through the interception channel, the large gas-liquid contact area and rapidly updated interface provide a quick reaction site for desulfurization, defluorination, and other reactions.

This technology allows for the efficient removal of impurity gases and is theoretically applicable with wet desulfurization equipment to achieve efficient desulfurization, defluorination, and the removal of various other acidic gases.

- Contact Us

- Technical Parameters

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom Interception-Type Wet Desulfurization Equipment Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

-

Hygienic Storage Tank is often chosen in critical processes precisely because it must maintain produ...

-

A Hygienic Storage Tank plays a crucial role in industries such as food processing, dairy, and pharm...

-

The stainless steel storage tank system is a foundational component for modern manufacturing in indu...

-

Every chemical processing facility that uses separation technology will encounter operational questi...

-

Integrating a Distillation Unit with an Extraction Unit is a frequent topic of discussion among chem...

En

En

русский

русский Español

Español عربى

عربى