High-Gravity Gas Absorption Unit

High-Gravity Carbon Capture,HGCC(Carbon Dioxide Absorption)

The baffle-type rotating bed is a highly efficient gas-liquid mass transfer device that intensifies the mass transfer process through centrifugal force. It is widely used in carbon capture (CO₂ capture) applications. Its core principle utilizes high-speed rotation to disperse liquid into ultra-thin films or micro-droplets, dramatically expanding the gas-liquid contact area and thereby significantly enhancing CO₂ absorption efficiency.

Get A Quote

- Contact Us

- Technical Parameters

ABOUT US

Zhejiang Xinchuangxing Technology Co.,Ltd.

Zhejiang Xinchuangxing Technology Co.,Ltd. is located in Longwan District, Wenzhou, Zhejiang. We are a high-tech enterprise integrating technology research and development, engineering design, production and manufacturing, installation, and debugging. We possess strong technical expertise and a large team of skilled professionals, which enables us to constantly develop new products aligned with industry trends, and actively commercialize technological breakthroughs. Our advanced equipment, built upon high-gravity technology, covers distillation, waste gas treatment, wastewater treatment, and other advanced systems, delivering significant energy-saving and emission reduction benefits, all while adhering to environmental protection principles and supporting sustainable development.

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

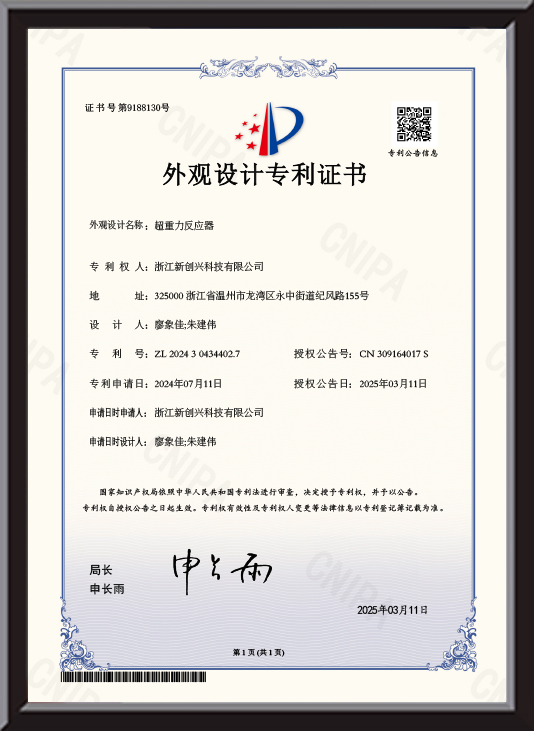

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom High-Gravity Carbon Capture,HGCC(Carbon Dioxide Absorption) Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom High-Gravity Carbon Capture,HGCC(Carbon Dioxide Absorption) Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

Latest Updates

What'S News

-

Hygienic Storage Tank is often chosen in critical processes precisely because it must maintain produ...

-

A Hygienic Storage Tank plays a crucial role in industries such as food processing, dairy, and pharm...

-

The stainless steel storage tank system is a foundational component for modern manufacturing in indu...

-

Every chemical processing facility that uses separation technology will encounter operational questi...

-

Integrating a Distillation Unit with an Extraction Unit is a frequent topic of discussion among chem...

En

En

русский

русский Español

Español عربى

عربى