High-Efficiency Rotary Nanomaterial Reactor

This reactor synthesizes nanomaterials via gas-liquid or liquid-liquid two-phase reactions. Particle morphology and size distribution can be precisely controlled to produce various nanomaterials, including nano calcium carbonate, nano aluminum hydroxide, nano sodium bicarbonate, and more.

Key process parameters—such as reaction temperature, reactant concentration, gas-liquid flow rate ratio, and the addition or removal of crystal form control agents—can be finely adjusted to achieve desired product characteristics. Specialized configurations are available for producing high-activity, high-specific-surface-area calcium hydroxide using high-speed rotation. Systems for nano calcium synthesis (gas-liquid reaction) and other liquid-liquid reactions can be supplied, with pilot-scale units available for experimental verification to ensure product feasibility. On-site application: Compared to similar reactors, this equipment can reduce electricity consumption by up to 50% under equivalent operating conditions.

- Contact Us

- Technical Parameters

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

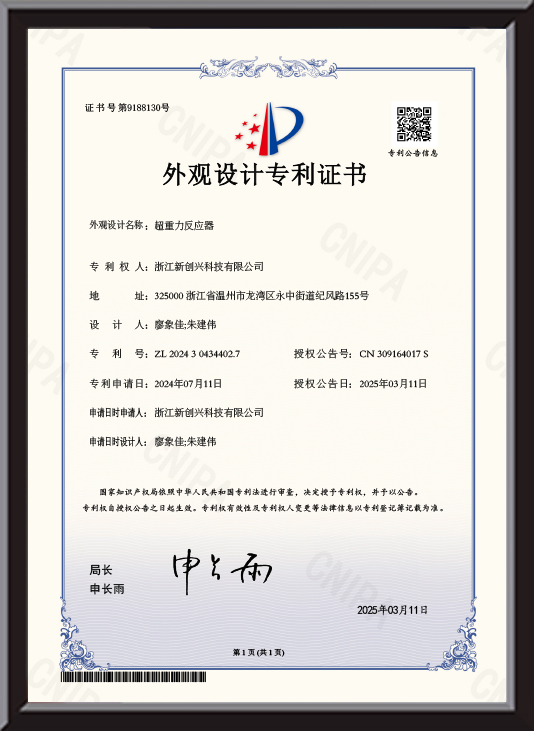

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom High-Efficiency Rotary Nanomaterial Reactor Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

-

Hygienic Storage Tank is often chosen in critical processes precisely because it must maintain produ...

-

A Hygienic Storage Tank plays a crucial role in industries such as food processing, dairy, and pharm...

-

The stainless steel storage tank system is a foundational component for modern manufacturing in indu...

-

Every chemical processing facility that uses separation technology will encounter operational questi...

-

Integrating a Distillation Unit with an Extraction Unit is a frequent topic of discussion among chem...

En

En

русский

русский Español

Español عربى

عربى