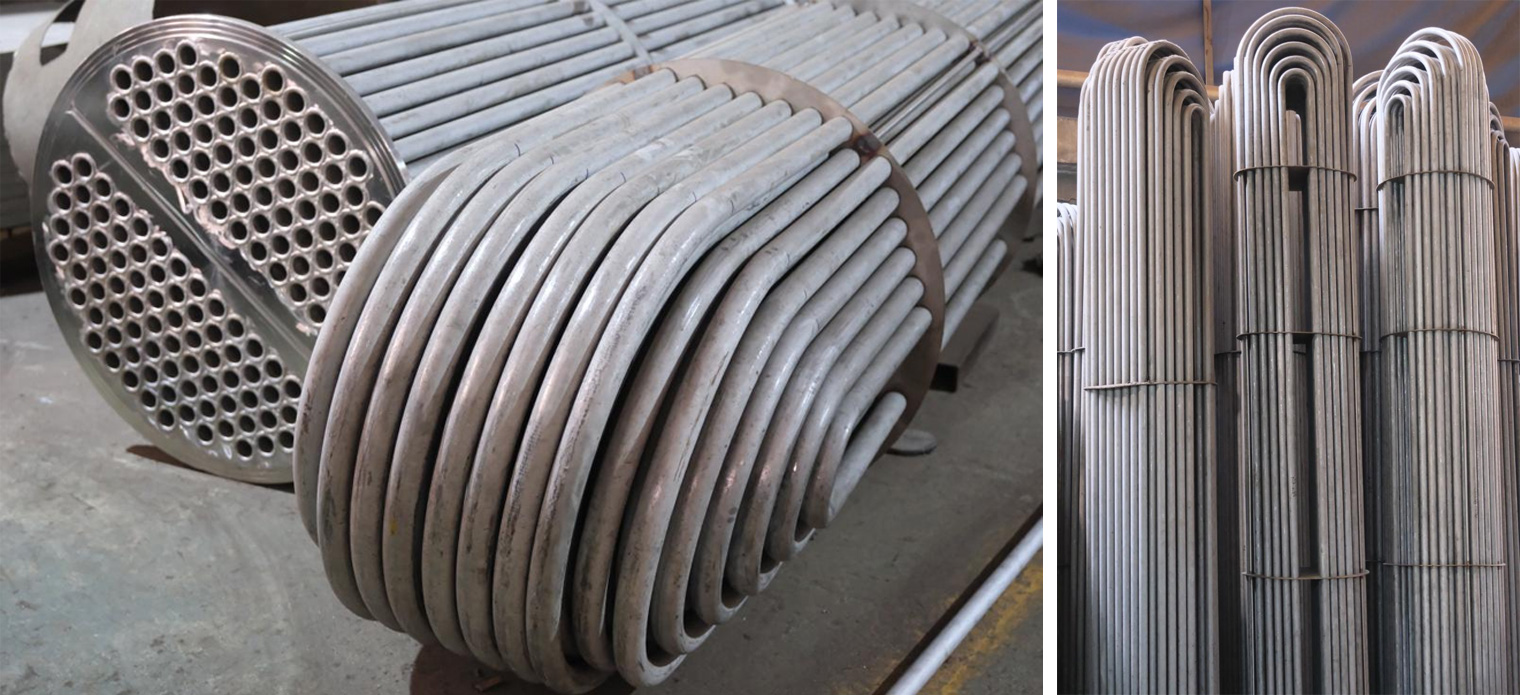

Horizontal U-Tube Shell and Tube Evaporator

Shell and tube heat exchangers are widely used in chemical, pharmaceutical, and refining industries to transfer heat between two fluids with a temperature differential. Our company has developed a horizontal reboiler, also known as a kettle evaporator, with an optimized design to increase heat transfer efficiency. This innovation helps save on factory investment and improves energy utilization. The shell side of the unit features a large evaporation area in its upper section. Fluid on the shell side vaporizes, enters this larger space, and exits through the upper outlet pipe.

Building on standard reboiler designs, we can optimize several key details to enhance heat transfer efficiency while reducing manufacturing and operating costs. This is achieved by increasing the heat transfer film coefficient on one side of the equipment’s internal heat transfer position, increasing the number of tube passes, and achieving an optimal length-to-diameter ratio. Additionally, the reboiler's bottom has a unique sinking structure that maximizes the utilization of internal equipment space and minimizes leftover liquid after evaporation.

- Contact Us

- Technical Parameters

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom Horizontal U-Tube Shell and Tube Evaporator Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

-

Hygienic Storage Tank is often chosen in critical processes precisely because it must maintain produ...

-

A Hygienic Storage Tank plays a crucial role in industries such as food processing, dairy, and pharm...

-

The stainless steel storage tank system is a foundational component for modern manufacturing in indu...

-

Every chemical processing facility that uses separation technology will encounter operational questi...

-

Integrating a Distillation Unit with an Extraction Unit is a frequent topic of discussion among chem...

En

En

русский

русский Español

Español عربى

عربى