Spiral Wound Heat Exchanger

High Heat Transfer Coefficient

The unique spiral-wound tube bundle optimizes the fluid flow on both sides, resulting in a heat transfer capacity per unit area that is 3 to 5 times higher than conventional heat exchangers. As a heater, it improves the utilization efficiency of the heat source; while as a condenser, it enhances material recovery rates and reduces refrigerant costs.

Long Service Life

The elastic tube bundle within the heat exchanger effectively absorbs both operational stress and vibration. This feature significantly prolongs the unit's lifespan, with a designed operational lifespan of up to 20 years.

Low Fouling Tendency

Featuring a unique Y-shaped interface, the heat exchanger has no dead zones, allowing for complete drainage of both the tube and shell sides. The high flow velocity in the shell side effectively reduces the probability of scale adhering to the tube surfaces, leading to a consistently low fouling tendency.

Compact Footprint

With a compact structure, this heat exchanger's volume is approximately one-fifth that of traditional heat exchangers under same operational conditions, leading to significant space savings and reducing load.

Low Operating Costs

For steam heating, it saves over a 10% on the steam consumption. For condensation, it achieves 1-3% higher recovery rates and enables lower condensing temperatures with the same refrigerant. Alternatively, to maintain a specific condensing temperature, it reduces the low-temperature refrigerant consumption, thereby lowering overall operating costs.

- Contact Us

- Technical Parameters

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

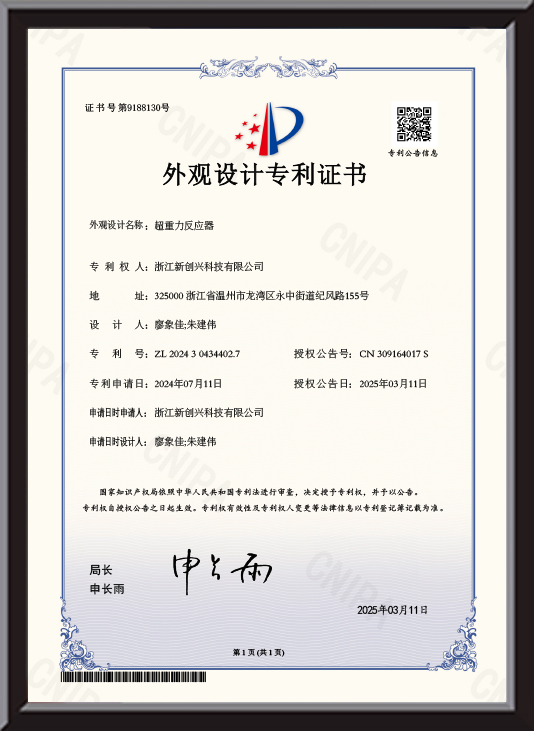

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom Spiral Wound Heat Exchanger Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

-

Hygienic Storage Tank is often chosen in critical processes precisely because it must maintain produ...

-

A Hygienic Storage Tank plays a crucial role in industries such as food processing, dairy, and pharm...

-

The stainless steel storage tank system is a foundational component for modern manufacturing in indu...

-

Every chemical processing facility that uses separation technology will encounter operational questi...

-

Integrating a Distillation Unit with an Extraction Unit is a frequent topic of discussion among chem...

En

En

русский

русский Español

Español عربى

عربى