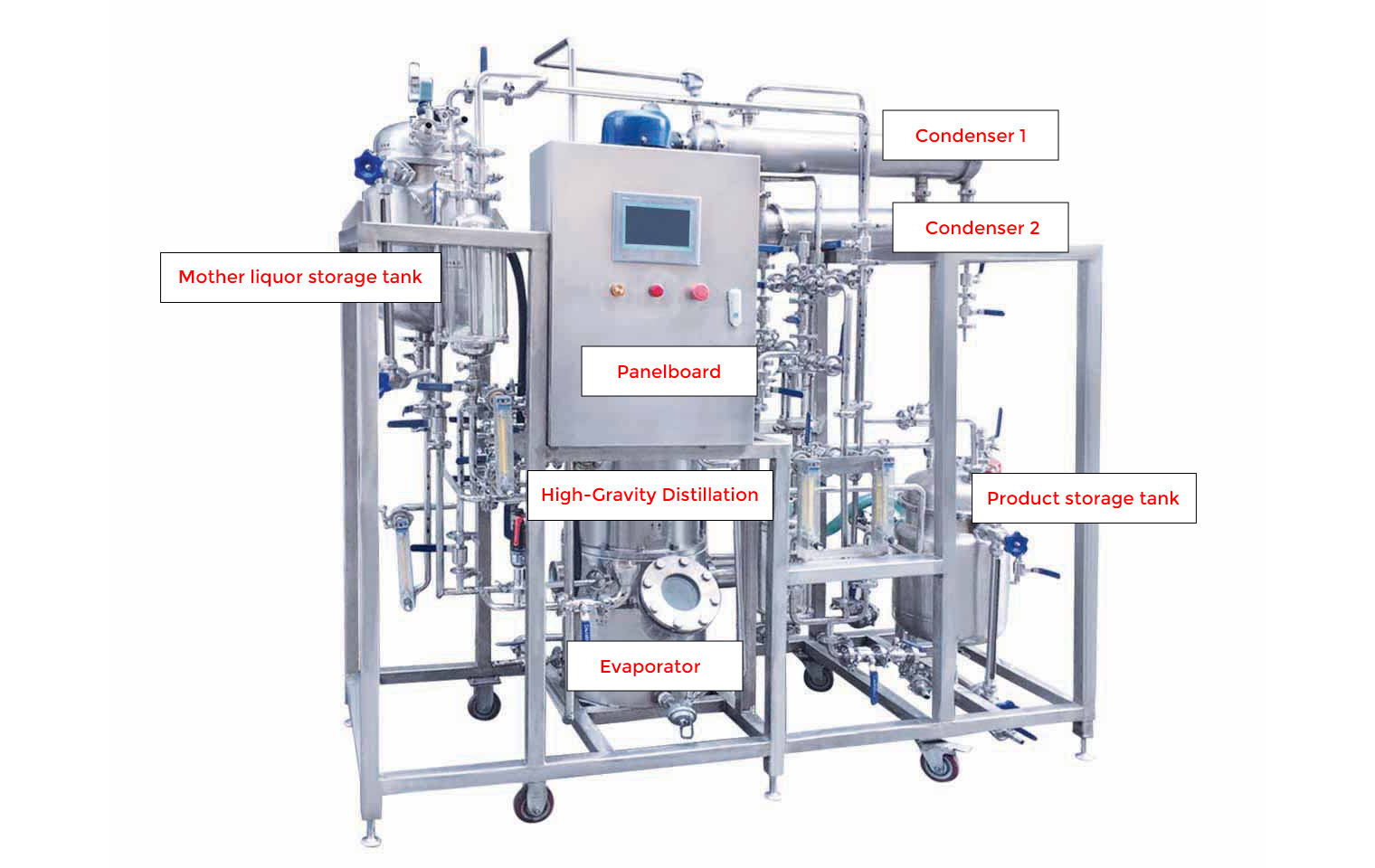

High-Gravity Distillation Small-Scale Experimental Unit

The rotary distillation prototype is comprised of several systems, including an electric-heated evaporator, the distillation unit, a raw material tank, a condenser, and a finished product tank. This system is designed to recover and purify organic solvents such as ethanol, methanol, acetone, ethyl acetate, acetonitrile, tetrahydrofuran, dichloromethane, DMF, DMSO, toluene, isopropanol, and tert-butanol. Once started, it quickly extracts and purifies the final product.

Principles of Distillation

The core principle involves using centrifugal force to increase the contact area and mass transfer rate between the gas and liquid phases. The unit is significantly more compact than traditional equipment because the liquid is more thoroughly dispersed, leading to better gas-liquid contact.

A specially designed rotor inside the machine body revolves at high speed. The liquid phase enters the rotor's center from the inlet, while the gas phase enters from the outer edge. Within the rotor, the gas-liquid phases create a gas-liquid interface with a large and continuously updated specific surface area, resulting in an extremely high mass transfer rate. The liquid phase is then collected inside the machine and led out, while the gas phase exits through a separate outlet.

Applications & Features

The rotary distillation machine we develop and build serves as an excellent demonstration tool for teaching and practicing distillation synthesis techniques at major chemical colleges, research institutes, and industrial companies worldwide. It features a compact system structure, is easy to disassemble and assemble, and offers high performance, efficiency, and convenient operation.

- Contact Us

- Technical Parameters

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

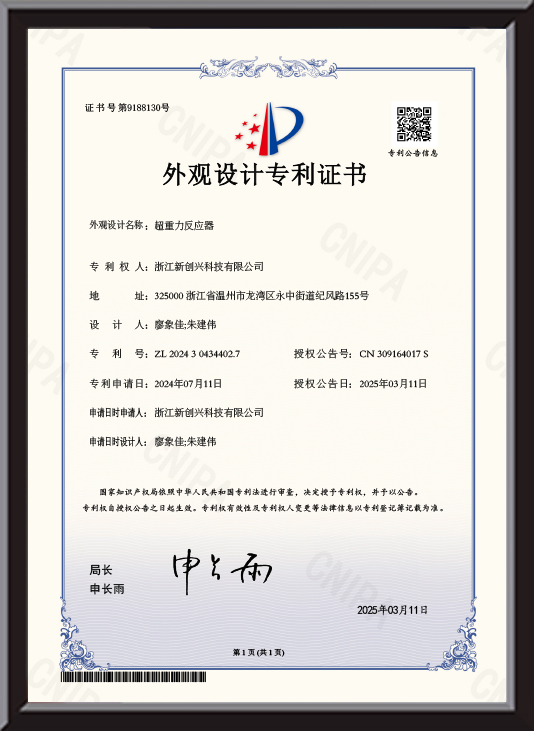

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom High-Gravity Distillation Small-Scale Experimental Unit Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

-

Hygienic Storage Tank is often chosen in critical processes precisely because it must maintain produ...

-

A Hygienic Storage Tank plays a crucial role in industries such as food processing, dairy, and pharm...

-

The stainless steel storage tank system is a foundational component for modern manufacturing in indu...

-

Every chemical processing facility that uses separation technology will encounter operational questi...

-

Integrating a Distillation Unit with an Extraction Unit is a frequent topic of discussion among chem...

En

En

русский

русский Español

Español عربى

عربى