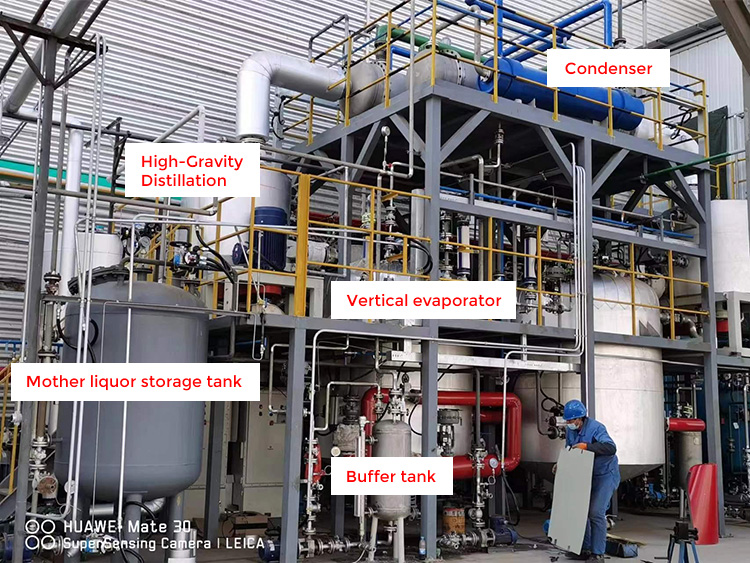

High-Efficiency Rotary Distillation Unit

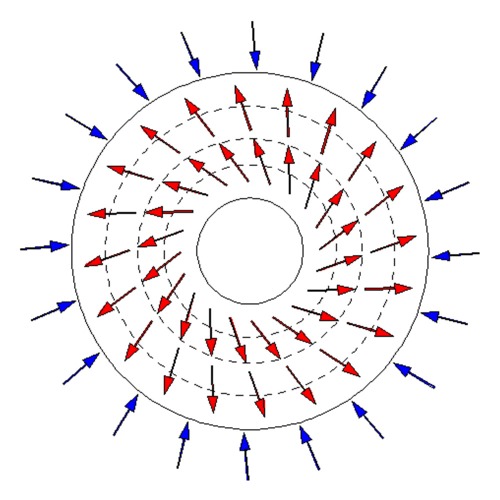

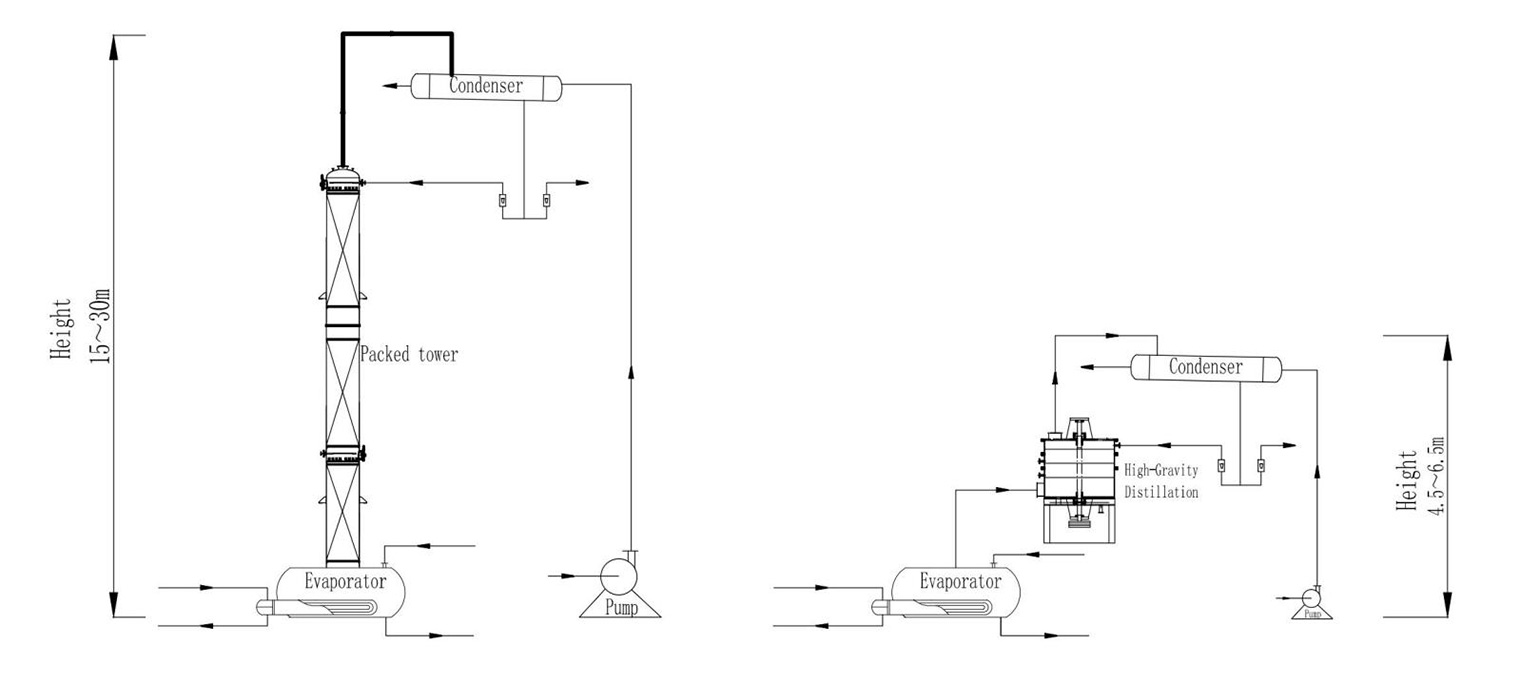

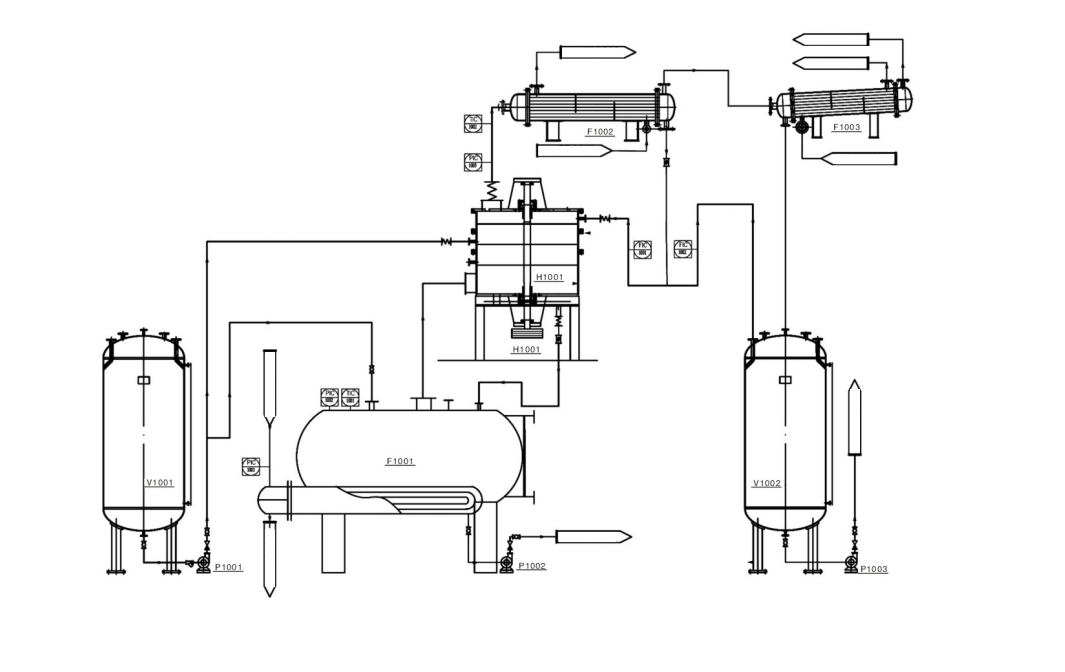

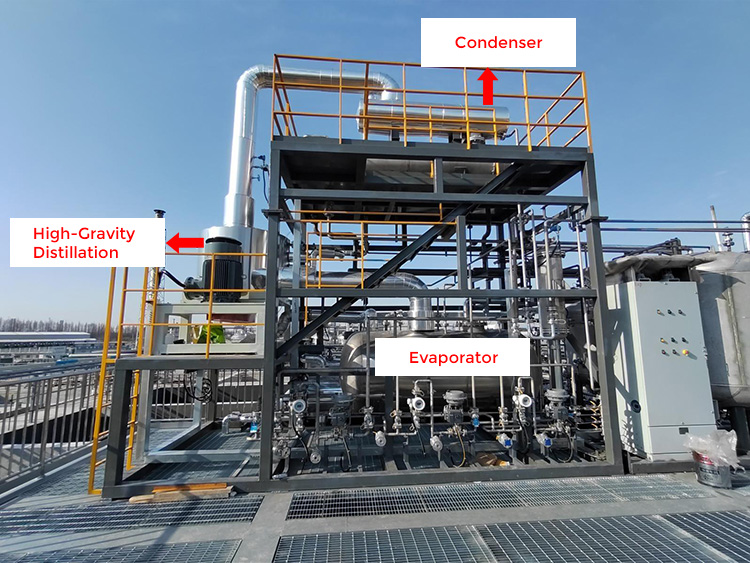

In the pharmaceutical and chemical industries, the recovery of organic solvents (such as methanol, ethanol, etc.) is typically achieved through distillation using gas-liquid mass transfer equipment like tray columns or packed columns. Due to the weak gravitational field, slow liquid film flow, and low mass transfer coefficients, such equipment is characterized by large size, low space utilization, low production intensity, and high capital investment. Therefore, our high-gravity distillation system serves as an excellent alternative to traditional distillation columns: with a high-gravity factor reaching 100–1000g, it dramatically reduces liquid film thickness and increases mass transfer coefficients by 1 to 3 orders of magnitude. The Height Equivalent to a Theoretical Plate (HETP) is significantly lowered, resulting in separation efficiency far surpassing conventional trays or packed columns. Owing to extremely rapid mass transfer rates, the height of a high-gravity distillation tower is only 1/10 to 1/5 of a traditional column, substantially saving space and material costs, making it ideal for confined spaces or mobile production. Additionally, its ultra-short residence time (on the order of milliseconds) minimizes degradation of heat-sensitive substances, while energy consumption is reduced by 20%–50% compared to conventional distillation/packed columns. In industries such as APIs, pharmaceutical intermediates, agrochemicals, and fine chemicals, organic solvents derived from extraction, reaction, elution, centrifugation, and filtration processes can be separated, purified, and recovered using high-gravity technology to meet reuse standards. Furthermore, high-gravity distillation can be coupled with Mechanical Vapor Recompression (MVR) to reduce energy consumption, integrated with pervaporation membranes to produce anhydrous solvents, and process mixed solvents from other industrial operations.

- Contact Us

- Technical Parameters

The company adheres to a corporate philosophy centered on "integrity, cooperation, and innovation." We consistently uphold our brand strategy, which is "market-driven, focused on R&D, meticulously designed, and service-oriented." Our commitment extends to creating an influential high-gravity technology platform and industrial cluster.

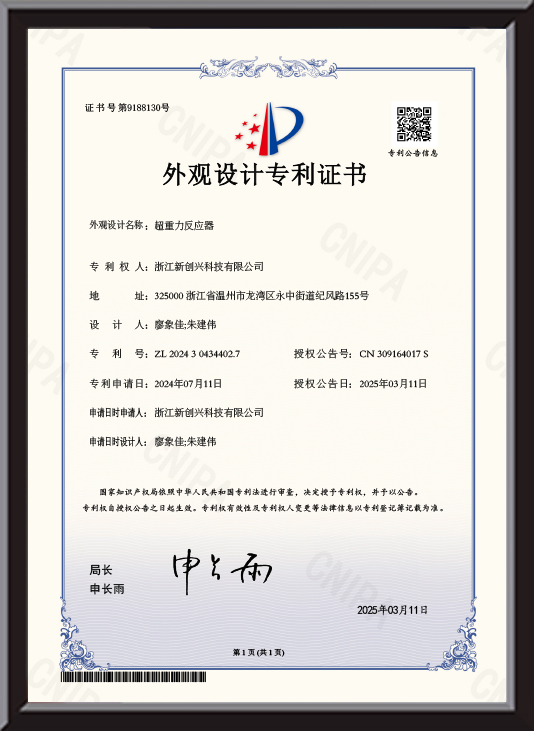

Located in a coastal region, Xinchuangxing benefits from a highly active raw material market, which provides a competitive edge in pricing and ensures superior quality. As a Custom High-Efficiency Rotary Distillation Unit Manufacturers, We have secured numerous patents and intellectual property rights related to high-gravity technology, demonstrating our exceptionally high technical and innovative capabilities.

-

Hygienic Storage Tank is often chosen in critical processes precisely because it must maintain produ...

-

A Hygienic Storage Tank plays a crucial role in industries such as food processing, dairy, and pharm...

-

The stainless steel storage tank system is a foundational component for modern manufacturing in indu...

-

Every chemical processing facility that uses separation technology will encounter operational questi...

-

Integrating a Distillation Unit with an Extraction Unit is a frequent topic of discussion among chem...

En

En

русский

русский Español

Español عربى

عربى